Table of Contents

What is gauge?

Imagine you are a plant manager and as a part of your regular activity you go for inspection visits on the shop floor. In one such visit, you thought of verifying parts produced by one of the operators.

How would you verify it? You would need some instruments to check. Right!. That instrument you need to verify part adherence to required standards is called gauge. The formal definition of Gauge is as follows.

Gauge is an instrument with or without scale that gives a visual display of the amount, level, or contents of something.

Gauges help us make important decisions required to produce parts as per customer requirements. If a supervisor has to give go-ahead for production, he can do so by verifying parts as per customer specification using various gauges. If a customer has to verify parts sent by any particular supplier, he can verify the same using various gauges.

In part manufacturing, we use multiple types of gauges depending on the usage. I have covered all kinds of gauges in this article. Keep on reading to understand all you need to know about gauges.

In case, I have missed any of the gauges as per your knowledge. Please comment in the comment section. I will definitely try to incorporate the same.

Why do we need gauges?

Imagine you have a car that does not have any indicators such as fuel measure, engine temperature, etc on your car dashboard.

How likely are you to find yourself with an empty fuel tank in the middle of your trip? I guess pretty often. I know it’s not a very desirable condition. By the way, the fuel level indicator is an indicator type gauge.

So a similar situation will be evident in production factories if they run their productions without gauges. Parts produced will be full of defects, there will be regular production halts. The factory floor will be a mess.

To enlist few benefits, why we use gauges are as follows :

- Helps produce quality parts in a consistent manner.

- Reduces production waste, as wrong parts would be caught before production.

- Helps factory build on proactive rather than reactive approach.

- Gauges help control all quality parameters specified in the control plan. Control plan encapsulates all the customer specified parameters. If you want to learn more about the control plan, I have written an article about the control plan. Do check it.

What are the types of Gauges?

Plug gauge

Plug gauge is a cylindrical dumble-like gauge. It has a go-section on one side and a no-go section on the other.

It is used to measure the inside diameter of a hole. It is an attribute type of gauge. Attribute gauge means it gives the only indication if a part is ok or not ok. It does not provide any variable value.

If the go-section enters the hole smoothly and No-Go Section does not enter the hole, then the part is OK as per specification. If Go-Section does not enter hole OR No-Go enters hole part is NG or NC in either case.

Plug Gauges have various grades such as XXX, XX, X, Y, Z, ZZ.XXX has the tightest tolerance reduction towards ZZ.

Ring Gauge

Ring gauge is used for checking outer diameter. As the name suggests ring gauge looks like a ring. Ring gauge has a set of Go ring gauge and No-Go ring gauge.

Ring gauge is also an attribute type of gauge.

If part qualifies in go gauge and does not qualify in No-Go Gauge, the part is accepted or part is considered to be OK as per specified tolerances. If the part does not qualify in Go-Ring Gauge OR does qualify in No-Go Gauge, the part is considered as Not OK or Non-Conforming.

Ring gauges can be used to measure outer diameters of pins, shafts, splines, fasteners, dowels, studs, and other machined cylindrical parts.

Ring gauges are used as a proxy for micrometer gauge and other instruments used to check the outer diameter of machined parts. It takes less time to validate parts using ring gauge as compared to micrometer.

Ring Gauges have various grades such as XXX,XX,X,Y,Z,ZZ.XXX has the tightest tolerance reducing towards ZZ.

Snap Gauge

Snap gauge is used for checking outer dimensions, such as outer diameter and thickness. These are also called gap gauges.

Ring gauges are used for checking cylindrical parts only, whereas Snap gauges are used for checking cylindrical and non-cylindrical parts.

Snap gauges are used for making quick decisions based on Go, No-Go gauge. One of the reasons for using snap gauges is the speed of inspection it offers.

Snap gauges are usually go/no-go gauges. This means that a single gauge has the capability to assess both the upper tolerance limit on the dimensional parameter being measured as well as the lower tolerance limit.

Snap gauges generally have a C or U shape.

Feeler Gauge

A feeler gauge is used for checking clearance between two mating parts. Feeler gauge is also called a thickness gauge. It comes in varied sizes varying from 0.04 mm to 1 mm.

Clearance between mating parts is a very important parameter and excessive clearance in some parts can lead to major problems. For example, if the clearance between the cylinder head and the cylinder block is high, it could lead to gas leakage.

Feeler gauge has an added advantage that it could be used for measurement in assembled parts. The flatness of the individual mating surface of the cylinder block and cylinder head can be checked using various methods but very few methods help inspection after assembly, feeler gauge is one of those.

Calipers

Calipers are used for measurement of part dimension. It is one of the most commonly used instruments in manufacturing plants.

It generally measures both inside and outside dimensions and has an external scale to correlate measurement.

Calipers are of multiple types.

Inside caliper

Inside calipers are used to measure the internal size of an object.

Outside Caliper

Outside calipers are used to measure the external size of an object.

Divider caliper

Compass, divider, and caliper are basically instruments that have two legs pivoted to each other at the top and are concerned with small-distance measurement or transfer.

Odd Leg Caliper

It has two legs and one is bent to do the measurement on stepped surfaces. Odd Leg calipers ( Hermaphrodite Calipers) are used mainly to scribe lines parallel to the edge of metal (or plastics) – they are used for much the same reason that a woodworker might use a Marking Gauge. Oddlegs can also be used to find the center of a disc by first estimating its radius then scribing a number of arcs from different points around the circumference. The various arcs will enclose a small area in which the center must lie and so can be judged.

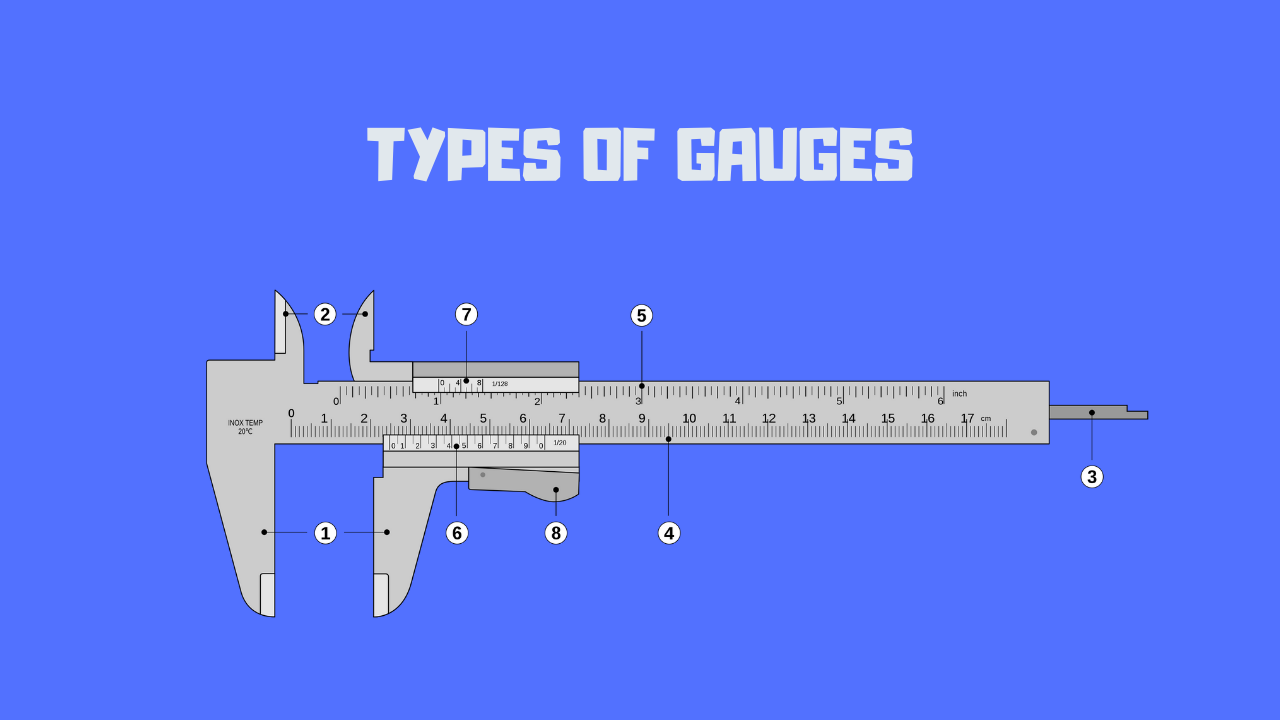

Vernier Caliper

Vernier Caliper is an instrument used to measure the distance between two points on a linear scale. It can be used for the measurement of outer, inner, and depth dimensions.

Analog Vernier Caliper has a least count of 0.02 mm and a digital Vernier Caliper has a least count of 0.01 mm.

Micrometer Caliper

Micrometer calipers are used for precise measurements. It has the least count of 0.001 mm i.e. one micron as the name suggests.

There are different types of micrometers used for checking inside, outside, and depth dimensions.

Dial Gauge

The dial gauge is an indicator type of gauge and comes in different least counts. There are two types of dial gauges plunger dial gauge and puppy dial gauge.

In simple terms, a dial gauge is used to measure deviations of any object from expected standards.

Dial gauges are used checking surface profiles,pressure,etc.

American Wire Gauge

American wire gauge, also known as the Brown & Sharpe wire gauge, is a logarithmic stepped standardized wire gauge system used since 1857, predominantly in North America, for the diameters of round, solid, nonferrous, electrically conducting wire. Dimensions of the wires are given in ASTM standard B 258.

Scale Ruler

A scale ruler is an instrument used for measuring lengths and transferring measurements at a fixed ratio of length.

Bridge Gauge

Bridge gauge helps measure fillet weld leg length and throat thickness, the height of weld reinforcement, depth of undercut, misalignment, and the angle of preparation. It is majorly used in welding shops.

Angle Protector

An angle protector is used for the measurement of angles. It is made of either plastic or metal.

Bevel Angle Protector

Bevel Angle protector is also used for angle measurement, but it can be used for different types of components and complicated shapes. It is typically used where normal angle protectors can’t be used.

Height Gauge

The height gauge is used for the measurement of the height of various objects. It is used in conjunction with a scriber, dial indicator, etc.

Height gauge has least count varying from 0.1 mm to 0.01 mm.

Checklist to maintain Gauge Condition

- Check the calibration status on the calibration sticker. The instrument shall be calibrated and the expiry date shall be greater than the present date.

- Clean gauges using benzene solution or any other cleaning solution.

- Keep gauges in the proper box or designated place.

- Gauges shall be kept away from the place of vibration.

- Keep gauges away from extremely hot conditions.

Good learned from these blog

There is evidently a lot to realize about this. I believe you made various nice points in features also. Sonya Bendix Eward

This is a very well written article. We manufacture most of these gauges and found this to be a good refresher. You can visit http://www.smitragauges.com for more information on these gauges.

I feel this is one of the such a lot important info for me. Kameko Frederik Gotcher

Looking forward to reading more. Great blog article. Want more. Bill Itch Modie

Dead written content material, Really enjoyed reading through. Karna Bern Ezequiel

I am not very wonderful with English but I line up this real easy to interpret.

Today, I went to the beach with my kids. I found a sea shell and gave it to my 4

year old daughter and said “You can hear the ocean if you put this to your ear.” She put the shell to

her ear and screamed. There was a hermit crab inside and it pinched her ear.

She never wants to go back! LoL I know this is totally off topic but

I had to tell someone!

lol @pam

I loved your article.Thanks Again. Will read on…

Excellent pieces. Keep posting such kind of info on your site.

Im really impressed by your blog.

Hello there, You have performed a fantastic job.

I’ll certainly digg it and in my view recommend to my friends.

I am sure they’ll be benefited from this web site.

Really appreciate you sharing this blog.Thanks Again. Will read on…

Wonderful post however I was wondering if you could write a litte more on thissubject? I’d be very grateful if you could elaborate alittle bit further. Thank you!

Great, thanks for sharing this post. Awesome.

Thanks for sharing, this is a fantastic post.Much thanks again.